Health and Safety Excutive

Sustainable development (qualitative and quantitative development with attention to environment and natural resources reservation) is the main axis of all Isfahan cement company programs and plans.

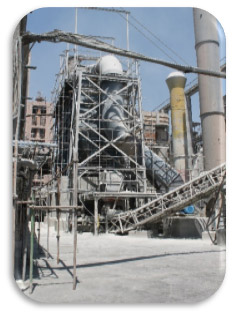

The Isfahan cement company has 3 production lines with the total capacity around 3200 ton per day .It should be mentioned that this company has two modern dedusting (dust collecting) systems of baghouses and 6 units of electrofilters and more than 40 systems of jetfilters and bagfilters which the exited dust is monitored by 3 online dust analyzers and will be reported to the environment administration of Isfahan province.

On other hand it should be said that 30% of factory surface is covered by green spaces and landscaping.

Environmental projects

- Utilization of third and fourth modern baghouse dedusting (dust collecting) systems related to the cooler of 500 ton exist line of 700 ton kiln electro filters.

- The start of executive operation for the project of elevator installation in raw material reservation hall instead of using the ceiling crane and cup for corrective material handling toward the cement mills. This project was performed for reduction of dust emission in surrounding environment.

- Installation and running of separator system for number 6 cement mill which will cause the increase of cement quality and reduction of energy consumption.

- The start of executive operation for the run of one covered feeder unit for feeding the clinker in cement mills. With purpose of dust emission prevention.

- The project of changing the 700 ton kiln electro filter to bag hose for better performance of dust control unit.

- Utilization of the project of changing the 700 ton kiln electro filter into the baghouse dedusting (dust collecting) system.